Electropolishing

When the ultimate surface finishing is required, electropolishing is the answer. All manufacturing processes expose the surface to some sort of degree of contamination or changes in the complex surface structure. Depending on the degree of machining, drilling, grinding, and polishing the structure of the material is changed through the introduction of heat from friction and quenching processes. In addition to metal structure changes, thin surface oxides are produced. All in all, these production methods deplete the performance of the base material in many ways. The mechanical section details illustrations that show influence of these processes and the depth of the surface that can be affected.

The Electropolishing process can be reproduced with a high degree of precision and consistency. Components that have tight tolerances made be processed safely under controlled conditions.

Optimising Surface Properties

The Electropolishing process removes a layer of material, typically between 5 – 30 um by non impact methods, exposing pure chemically clean material that is free from contamination and exceptionally smooth. These key factors optimise the surface properties to their full potential. The surfaces tend to be slightly nickel and chromium enriched allowing full passivity and optimising the full corrosion resistance of the material.

Roughness

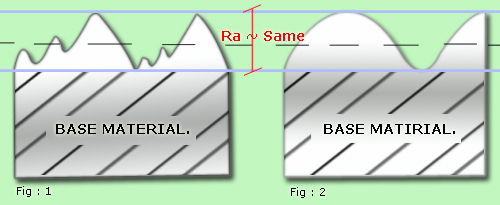

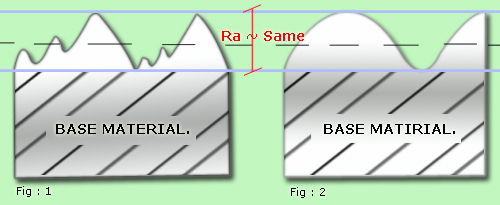

The roughness of a surface has a great affect on how it performs in service. In order to understand this fully the surface of the material must be look at very closely. Normal roughness stylus measures do not give enough information when requiring hi tech surfaces that are ultra clean, promote hi flow and reduce adhesion. Below shows a simple illustration that explains this:-

Fig1 shows a mechanically treated surface that has sharp peaks and troughs. Fig 2 shows a smooth flowing surface with the same Ra reading as Fig1. It is easy to see that Fig 2 has a much better surface finish that Fig 1.

A good example of this would be to have a 120 grit surface electropolished and compare it to a 400 grit mechanically treated. Both would show similar Ra reading, however the electropolished surface would have the optimum performance characteristics including:-

- Higher Corrosion Resistance

- Chemically Clean

- Low Surface Adhesion Properties (Non Stick)

- Aesthetically Pleasing (Shinny)

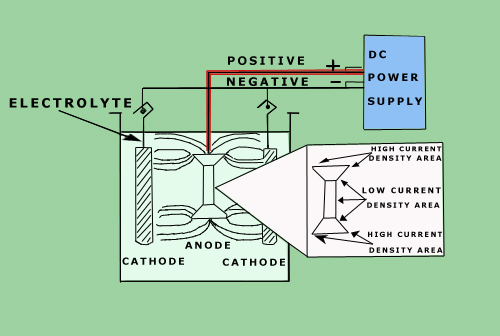

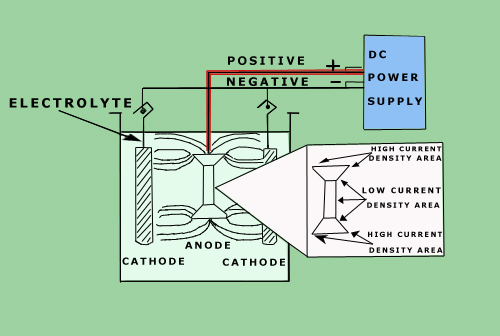

Electropolishing Process

The electropolishing process is in principal the reverse of electroplating. Electropolishing removes a relatively thin layer of material from the surface by dissolution through and electrolyte and a DC transformer. Schematic Below:-

This is typical schematic of the electropolishing process as the peaks are removed at a faster rate that the troughs. This removes the micro roughness of the surface, leaving a very smooth surface. Illustration below show the process:-