Cleaning Degreasing

Materials from mills and stockist are often stored for long periods of time and transported within areas susceptible to contamination. So from the outset, materials should be cleaned before fabrication process takes place, especially when the material is to undergo heat treatment processes such as welding. Such contaminants are absorbed into the material when taken into the molten state that greatly affect the performance of the surface properties, making it difficult to obtain uniform aesthetic surfaces finishes.

Throughout the manufacturing process components are subjected to handling, coolants and localised grease from numerous sources. Before any chemical processing takes place the components should be fully cleaned and degreased.

Pickling & Decaling

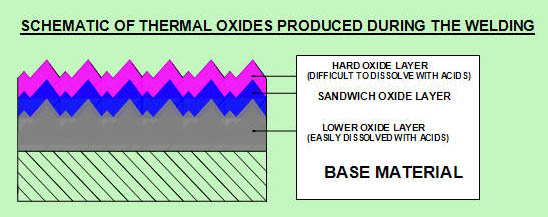

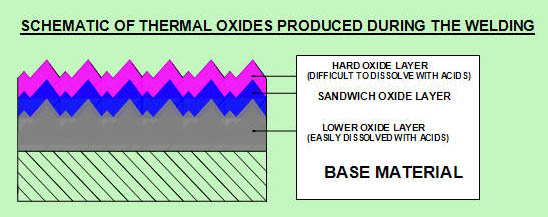

When stainless steel alloys are introduced to heat treatment processes, oxides are produce that reduce the surfaces ability to maintain its passivity thought the thin inert oxide protective layer. The oxides not only affect the appearance of the component but greatly reduce their corrosion resistance due to the oxides being mainly ferric oxides which are must less resistant. With these ferric oxides present it is not possible the material to produce its own natural uniform passive and leads it subject to various types of corrosion.

Below is an illustration of a typically welded surface

As mentioned in previous sections mechanical processes often hide contaminants. It is therefore crucial to remove these oxides layers to expose clean material. Standard pickling methods consist of aggressive mixed acids that dissolve these oxides in preference to the base material. Typically between 2 – 5 um are removed in this process leaving a matt etch appearance that is:-

- Metallically Pure

- Free of Discoloration

- Have Full Corrosion Resistance

- Have a Metallic Grey Etch Uniform Appearance

Acid pickling may be carried out in the following operations:-

- Immersion in a Solution

- Spray Solution Processing (within specialist enclosures)

- Brush or Roller on Paste

- Spray

Anodic Pickling

This process employs the use of a direct current rectifier and using much less aggressive solutions but require much more equipment. Typically these processes are used within automatic high volume specialist installations.

|